Classification : News HotspotsDate:2024-08-28Browse : 669

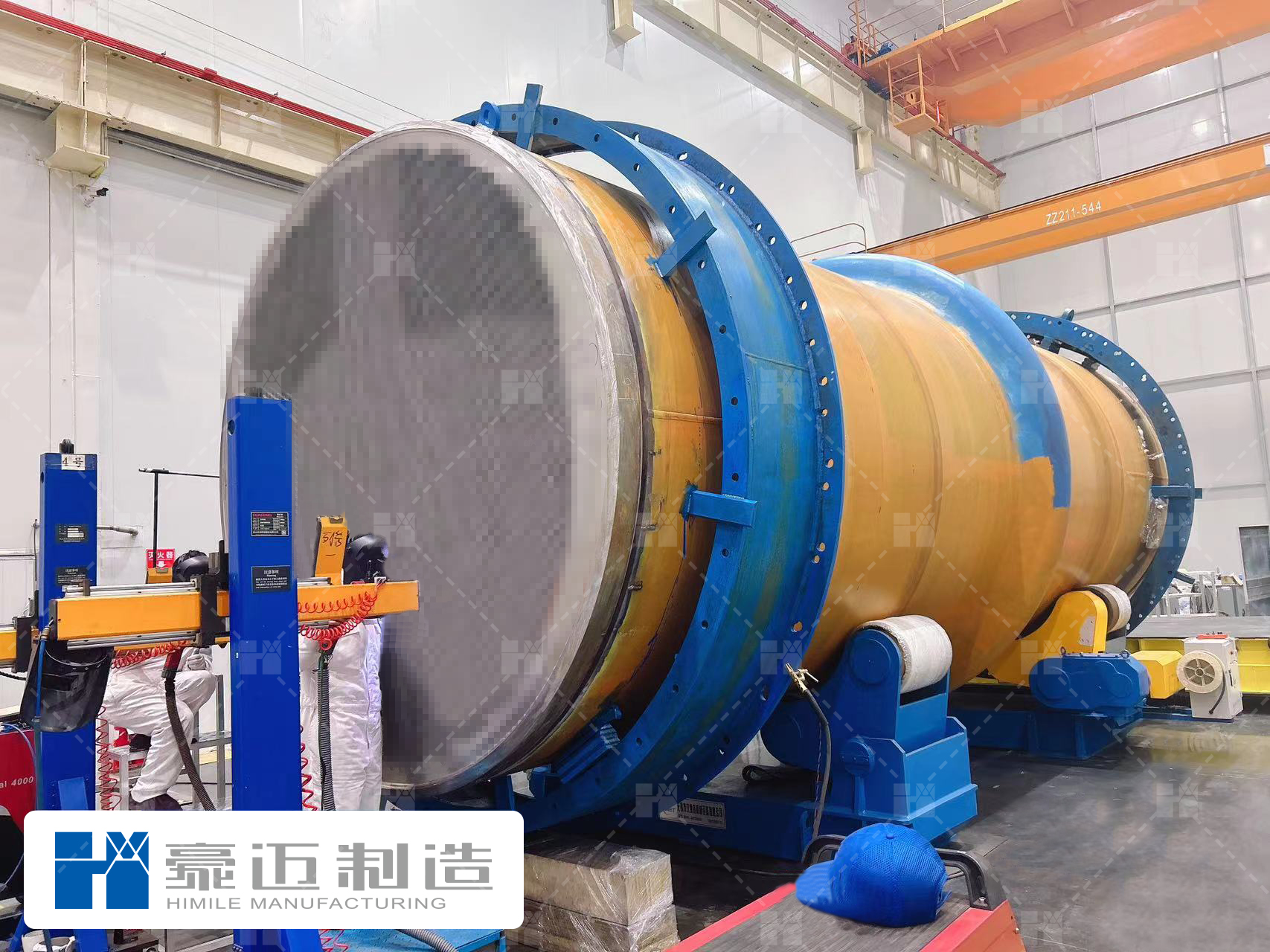

On August 27th, the "Sinopec Hunan Petrochemical Environmental Protection Epichlorohydrin New Process Epoxidation Reactor Localization Development Equipment-Factory Acceptance Witness Ceremony" was held at Himile.

This project has been included in the national "14th Five-Year Plan" key scientific and technological research and development catalog, led by Sinopec. The green chemical technology it adopts is an innovative achievement pioneered by Sinopec International and has complete independent intellectual property rights. Compared with traditional production processes, this technology can significantly reduce material consumption and emissions of the Three Wastes. After being completed and put into operation in March 2025, it will become a revolutionary change in the epichlorohydrin industry.

The reactor manufactured by Himile is the core equipment of this project, which is the first set in China. The material corrosion performance requirements are extremely high, welding and heat treatment are very difficult, and manufacturing and assembly requirements are quite tough.

One of the breakthrough points of this reactor is the successful application of a domestically produced special material - which has significant differences in properties from ordinary metals and is extremely difficult to weld.

“BE BRAVE TO INNOVATE, GO ON EXCEEDING " is the spirit of Himile, after more than 100 times of welding and corrosion tests, Himile has locked in the optimal welding parameters, making the annual corrosion rate of the reactor perfectly meet customer requirements. In addition, due to the high sensitivity of this special material to environmental impurities during welding, the entire welding process is completed in a 1,000,000-class cleanroom.

1,000,000-class cleanroom: a cleanroom where the number of dust particles with a diameter greater than or equal to 0.5 microns per cubic meter of air is less than 1 million. Personnel need to go through the air shower room for dust removal and change into clean work clothes before entering.

Finally, the complete localization of the reactor from process development to material procurement to production and manufacturing is achieved at Himile.

Himile has been deeply involved in the fields of fine chemicals and oil and gas equipment for more than ten years, accumulating rich experience and strength. In the future, Himile will take this as the bedrock, forge ahead in the field of high-end chemical equipment, manufacture world-class chemical equipment, and contribute Himile's strength to the transformation and upgrading of China's chemical equipment industry!